Company History

-

1923

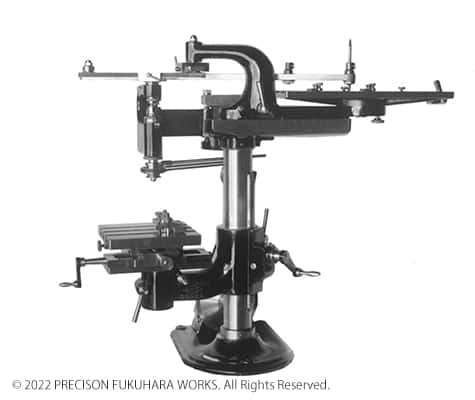

Fukuhara Tomosuke Shoten was established in Osaka and started to import/export textile machinery.

Fukuhara Tomosuke Shoten was established in Osaka and started to import/export textile machinery. -

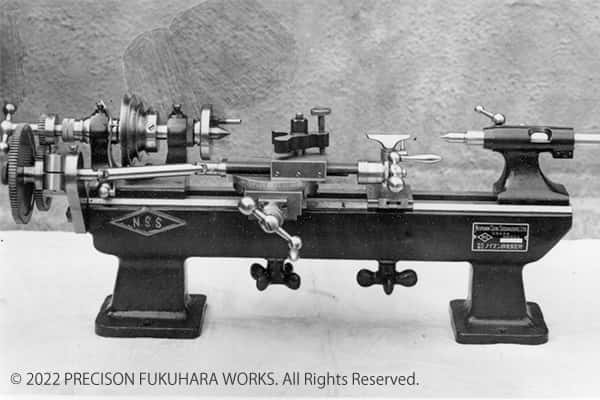

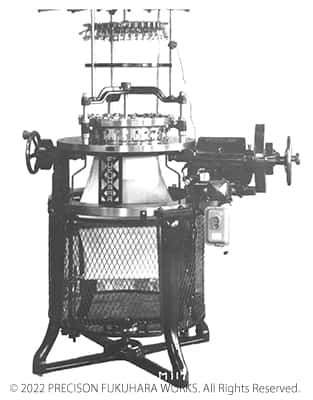

1938

Production of 6 feet lathes began and the company was established.

-

1945

The company was renamed to Fukuhara Industrial & Trading Co., Ltd.

-

1956

Manufacturing division was separated from Fukuhara Industrial & Trading Co., Ltd. to be an independent company as “Precision Fukuhara Works, Ltd.”.

Manufacturing division was separated from Fukuhara Industrial & Trading Co., Ltd. to be an independent company as “Precision Fukuhara Works, Ltd.”.

Shozo Fukuhara was inaugurated as President of Precision Fukuhara Works, Ltd.. Main machine models then produced: STS-L, STS-M, STS-P, FIL, FIL-D, MF, MF-T, RIM and JWS

-

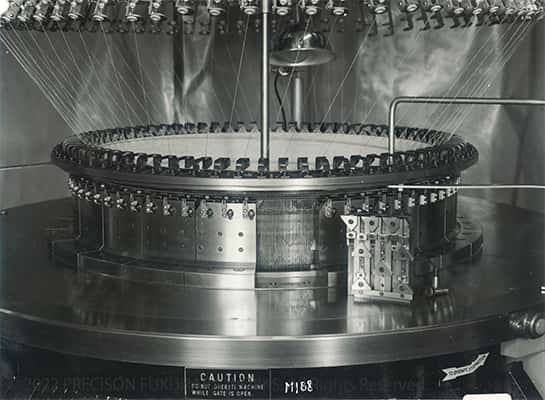

1961

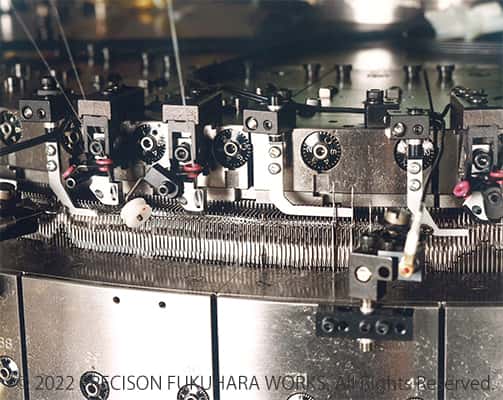

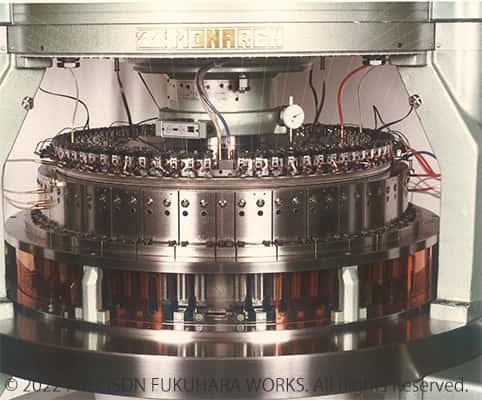

Business/technical collaboration contract was concluded with Monarch Knitting Machinery Corp. in USA. Model PFW, pattern wheel single knit jacquard machine

Cylinder exchange system for gauge alteration on single knit machines -

1963

FJ-3R (precision-enhanced single knit raceway machine) equipped with square cam set pieces for the first time in the world.This model further devolved into the world’s renowned FJ-4R.

Participated for the first time in #46 KAE (Knitting Art Exhibition) in held USA and fully entered into the US market through Monarch Knitting Machinery Corp.

Participated for the first time in #46 KAE (Knitting Art Exhibition) in held USA and fully entered into the US market through Monarch Knitting Machinery Corp.

-

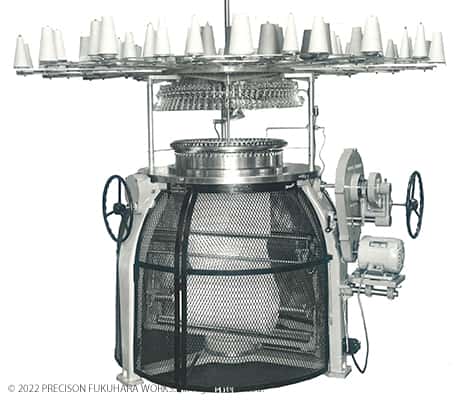

1967

Participated for the first time in ITMA held in Basel, Switzerland and started marketing in Europe.

JIL-7 in 28 gauge, the best selling machine in Japan

JIL-7 in 28 gauge, the best selling machine in Japan

-

1968

XL frame, platform for single knit convertible series. Launched convertible machines on the market.

XL frame, platform for single knit convertible series. Launched convertible machines on the market.

-

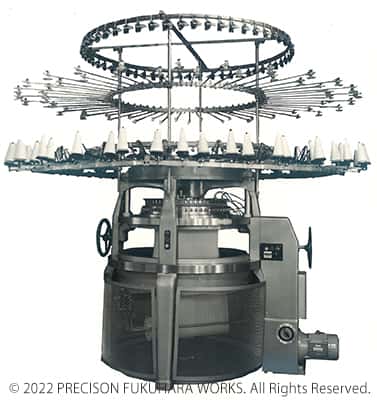

1970

L frame, new frame for double knit machines

LJW-60, double knit design-wheel jacquard machine with multi-feeders -

1973

LEC-48, double knit electronic needle selection machine

LEC-48, double knit electronic needle selection machine

-

1974

LIM-108A equipped with the world’s first closed cam systemThis model greatly enhanced knitting performance and productivity.

LIM-108A equipped with the world’s first closed cam systemThis model greatly enhanced knitting performance and productivity.

-

1978

SEC-24S, the world’s first single knit electronic 3-position needle selection machine

-

1980

SEC-24Y, the world’s first single knit electronic needle selection machine with 4-color auto-stripers

-

1981

Double knit auto-stripers

-

1984

SEC-36Y, single knit electronic needle selection machine with auto-stripers

-

1985

Knitting Technology Research Laboratory was completed.

Knitting Technology Research Laboratory was completed.

-

1984

SEC-36Y, single knit electronic needle selection machine with auto-stripers

-

1988

FX-Z4S (single knit machine) was developed.

-

1995

The head office/factory was totally damaged in the Great Hanshin Earthquake.

-

1996

Seishin factory was built in Seishin Science Park in Nishi-ku, Kobe to be engaged in machining of knitting machine parts. V-SECPL, single knit electronic sinker selection machine

-

1997

The head office/main factory was re-constructed in Higashinada-ku, Kobe.

-

1999

The factories acquired ISO9001 certification. V-LEC4D, double knit machine having both cylinder and dial electronic needle selection

-

2000

V-LEC4DGTY, double knit garment strip machine having both cylinder and dial electronic needle selection with 4-color auto-stripers

-

2001

ATSS (Automatic Tape Speed System) and ACSS (Automatic Central Stitch System)

-

2003

V-AERGY, double knit garment length machine with 4-color auto-stripers

-

2004

VX-SECWY6, single knit electronic needle selection machine with a wrap insertion mechanism and 6-color auto-stripers

-

2005

VX-RSY3RE, single knit electronic needle selection machine with 3-color auto-stripers

-

2006

V-FY3, double knit multi-feeder machine with 3-color auto-stripers

OD4-VXC-A3, single knit raceway machine with open width take-up device -

2007

V-LEC4DSI, double knit electronic jacquard machine with needle selection systems on both cylinder and dial

<World’s first ultra-fine gauge, 36G, electronic jacquard machine>

V-LEC6BSD & V-LEC7BSD, double knit electronic needle selection machine

V-SEC4BFY6, single knit electronic needle selection machine with 6-color auto-stripers -

2008

V-LEC4DGTFY6, double knit garment-length electronic jacquard machine with both-side needle selection

-

2009

Single knit ultra fine gauge (60G) machine, VXC-S3.2 was developed. Seishin new factory building was inaugurated. PFW’s Higashinada headquarters were moved to and integrated into Seishin factory on this occasion.

-

2010

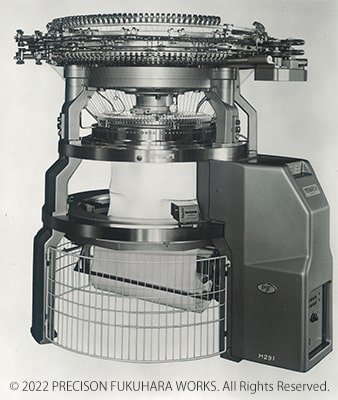

Developed M-LEC8BSC, a dedicated multi-feeder mattress ticking Machine.

With 38 inches and 108 feeders, the productivity of mattress ticking is dramatically improved. -

2011

Developed of next-generation single jersey raceway E3.2RE.

Developed of M-LEC6DSIB, a multi-feeders full jacquard on both dial & cylinder. -

2012

Developed of MX-3.2FY3RE, a multi-feeder with auto striper.

-

2013

Developed the quarter gauge knit M-4ALQG and proposed a new circular knit to the industry.

Developed of HXC-Z4SBP, an ultra-high-speed single jersey raceway machine.

Speed factor is 1750 and overwhelming productivity. -

2014

Developed of MX-S1.6CDF, a three end fleece machine for course gauges.

-

2015

Developed of M-LEC8BSH, Ultra-high-speed mattress ticking machine.

Developed of MX-SECPLFY3ME, full jacquard on both cylinder & sinker.

Achieves mesh + pile knitting that has never been seen before. -

2016

Developed of M-LEC7BSH, Ultra-high-speed mattress ticking machine.

Developed of MX-JS3D, an ultra-fine gauge semi-jacquard machine. -

2017

Developed of M-7DSIB, a multi-feeders full jacquard on both dial & cylinder.

Developed of M-4.0MI, a multi-feeders interlock machine. -

2018

Developed of LEC4DSCFY5, a double jersey with auto striper full jacquard machine. The newly developed stitch canceling mechanism makes it easier to organize multi-colored jacquards. Concluded a partnership agreement on needle oil with a super major French petrochemical manufacturer TOTAL. Pursuing higher performance needle oil and machine oil with TOTAL.

-

2019

Developed of next-generation single jersey raceway machine M2XC-A3.2RE with improved knitting performance and energy-saving performance.

At the same time, we developed a OD7 frame equipped with a OD7 open width device. -

continued to the present